The new technology, the Ultra High Efficiency Gas Turbine With Stator Internal Combustion, UHEGT, deals with a new concept for the devolvement of power and aircraft gas turbine engines, where the combustion process takes place within the turbine stator rows, leading to a distributed combustion. The UHEGT-concept allows eliminating the combustion chamber resulting in high thermal efficiencies which cannot be achieved by any gas turbine engines of conventional design. The concept of the UHEGT was developed by Schobeiri described in [2] and [3]. A detailed study in [3] shows that the UHEGT-concept drastically improves the thermal efficiency of gas turbines from 5% to 7% above the current highest efficiency of 40.5% set by GT24/26 at full load. To demonstrate the innovative claim of the UHEGT-concept, a study was conducted comparing three conceptually different power generation gas turbine engines: GT-9, a conventional gas turbine (single shaft, single combustion chamber), a gas turbine with sequential combustion (concept realization by ABB:GT24/26), and a UHEGT. The evolution of the gas turbine process that represents the efficiency improvement is shown in Figure 1.15.

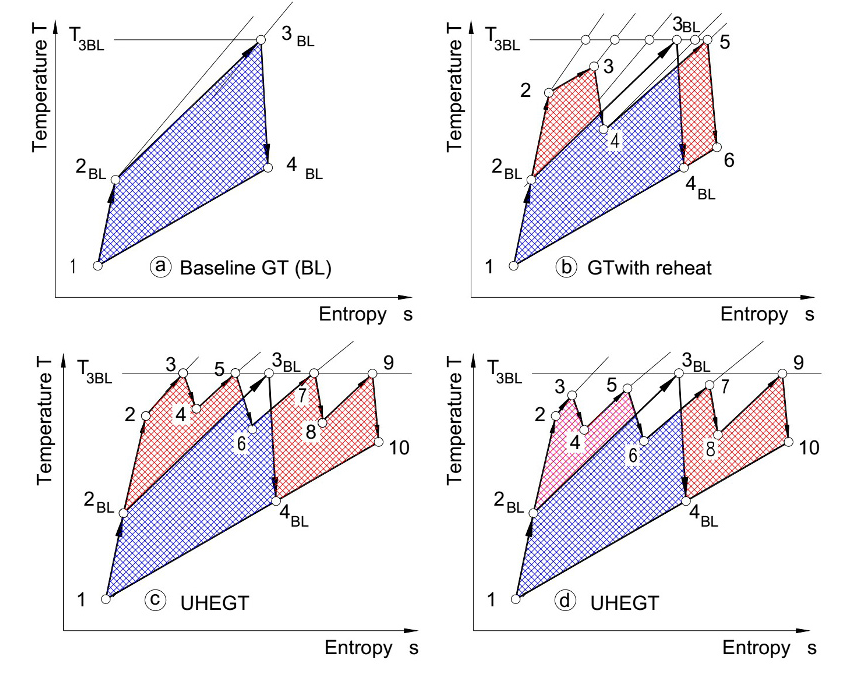

Figure 1.15: T-s-diagrams of three different bas turbines.

Starting with the base load process, Figure 1.15 (a), the first improvement is shown in Figure 1.15 (b), where the red hatched areas add to the T-s area leading to a substantial increase of thermal efficiency. The stator internal combustion represented by the UHEGT-concept shown in Figure 1.15 (c), shows a further increase of the T-s area and thus the thermal efficiency. In Figure 1.15 (c) the stator inlet temperature is kept constant. However, as shown in Figure 1.1 (d) the stator inlet temperature might be less than the maximum desired one within the first two stages. A quantitative calculation of each process is presented in Figure 1.16.

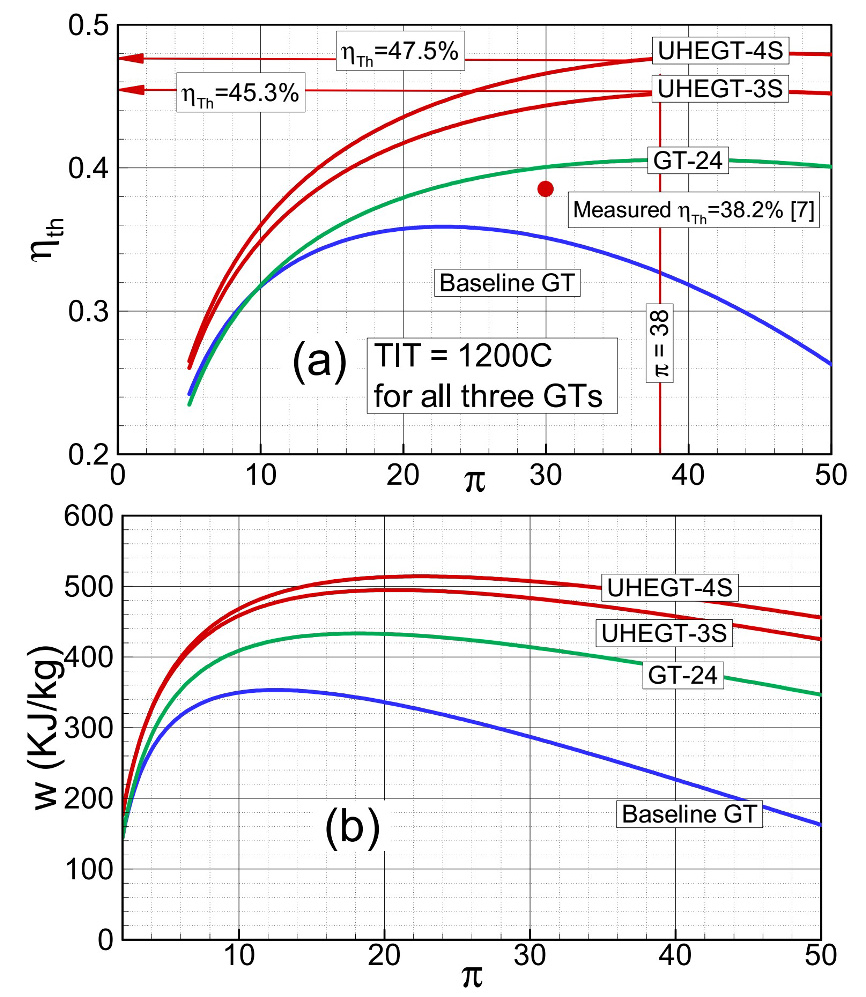

Figure 1.16: Comparison of (a) thermal efficiencies and (b) specific work for Baseline GT, GT24/26 and UHEGT.

It compares the thermal efficiency and specific work of baseline GT, the GT24/26, and a UHEGT with three and four stator-internal combustion, UHEGT-3S and UHEGT-4S, respectively. Maximum temperature, TIT, for all cycles are the same and equal to 1200◦ C. As shown in Figure 1.16, for the UHEGT-3S a thermal efficiency above 45% is calculated. This exhibits an increase of at least 5% above the efficiency of the current most advanced gas turbine engine which is close to 40%. Increasing the number of stator internal combustion to 4, curve labeled with UHEGT-4S, can raise the efficiency above 47% which is an enormous efficiency increase compared to any existing gas turbine engine. It should be noted that UHEGT-concept substantially improves the thermal efficiency of gas turbines, where the pressure ratio is optimized corresponding to the turbine inlet temperature. This gives UHEGT a wide range of applications from small to large size engines.

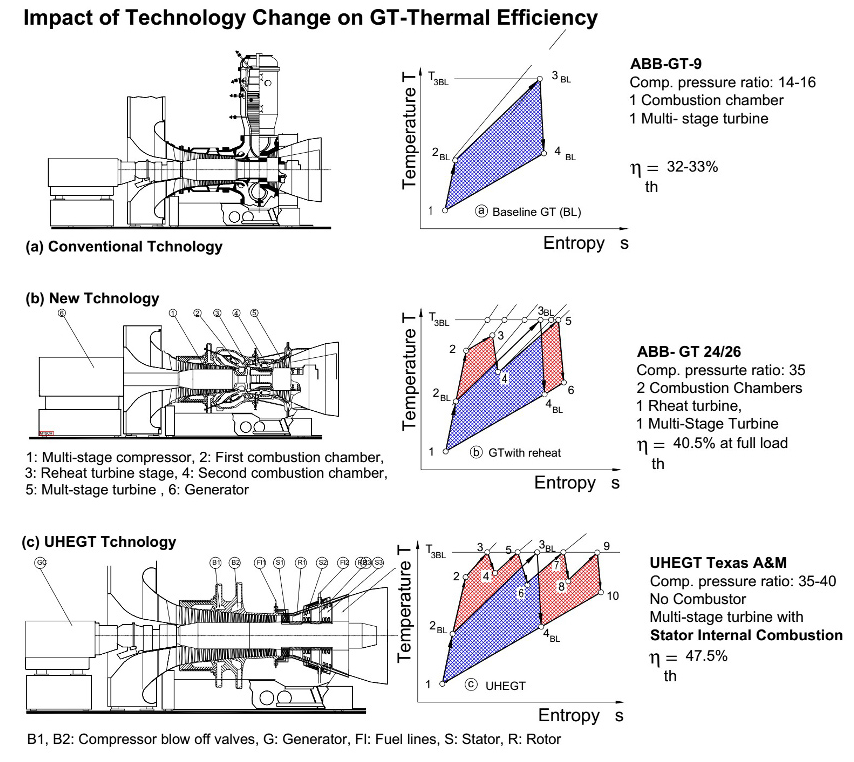

Figure 1.17: Technology change: Substantial increase of thermal efficiency at a moderate level.

Figure 1.17 summarizes the impact of technology change on thermal efficiency. It is remarkable that theefficiency increase of the UHEGT of 7.5% above the best existing GTs has been achieved without substantially raising the TIT.

Leave a Reply